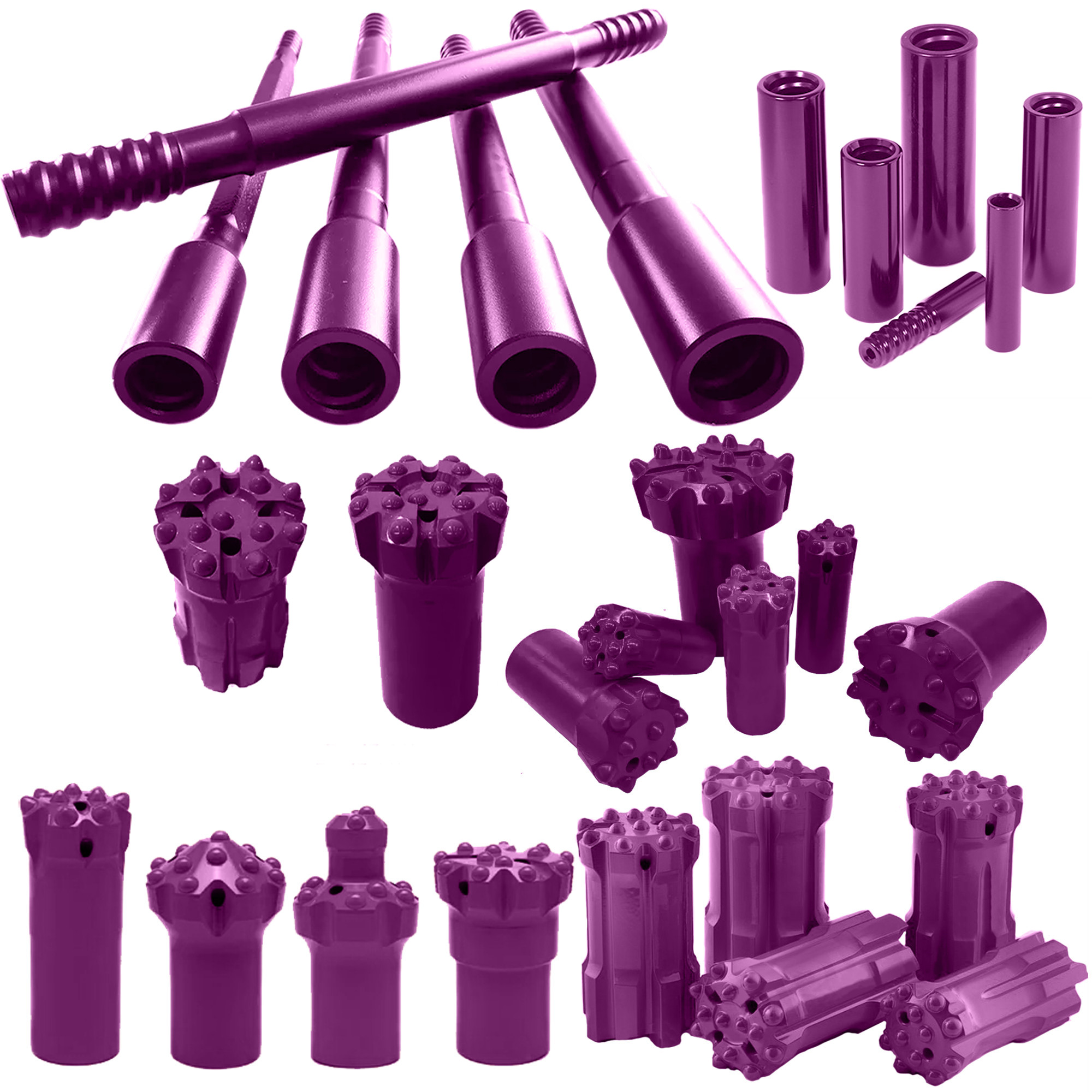

Tricone Drill Bits Hard Formations Drilling 9 7/8 Inch 251mm Mining Tricone Bit For Sale

Description

Brand Name:Sanrock

Place of Origin:Zhejiang, China

Type:DRILL BIT

Product name:Tricone Drill Bit

Diameter:251mm

Thread:6 5/8" API REG

Connect thread::API standard pin or customized

Machine Type:Drilling Tool

Advantage:Wear Resistant,High Performance

Bearing type:open/sealed bearing, rubber/metel seal bearing

Material:Carbon steel,High Manganese Steel, Diamond,Tungsten Carbide

Processing Type:Forging

Application:oil field, water well, geothermal, underground foundation,Coal Mining

Formation:soft rock formation,medium hard formation,hard rock formation.

Packing:Wooden Case,packing according to customer's requirement.

Specifications

| 1.Tricone bit connection made according to API standard. 2. The strength and wear resistance of inserts are improve by using carbide inserts with high strength and high wear resistance. 3. Surface of the high precision bearing heat treated by using advanced heat treatment process to improve the load capacity and service life of the bearing. 4. The service life of the bearing is further extended by adopting harder and more wear resistant material for thrust bearing. 5. This series oil well rock bit use sealed roller bearing structure. With rollers arranged in grooves recessed in the cone body, the size of the bearing journal is increased. 6. Thrust bearing surfaces are hard faced and treated with friction reducing technology. 7. Rotary drill bits use journal bearing. Hard faced head bearing surface. Cone bearing inlaid with friction reducing alloy and then silver-plated. The load capacity and seizure resistance of the bearing is greatly improve. |

|

|

|

Application

|

Tricone bit used tool oil field, water well, geothermal, underground foundation,Coal Mining. Which some may also call roller cone bits or tri-cone bits, have three cones. Each cone can be rotated individually when the drill string rotates the body of the bit. The cones have roller bearings fitted at the time of assembly. Tricone bit has the function of impacting, crushing and shearing rock in formation, so it can adapt to soft, medium and hard formation. Notes for the use of roller cone bits: |

|

Related downloads

Related products

Product consultation

Everything great in our world started with a conversation. Whether that’s easiest for you via a phone call, an email, or a text message, hit us up and let’s talk about your project. we’re here to help when you’re ready.

Phone : +86-5707779993

Tel : +86-15257031180

Email : info@sanrock.com.cn

Whatsapp : 86-15257031180

Copyright 2021 Sanrock Inc. All rights reserved. 浙ICP备2022010184号-1