News center

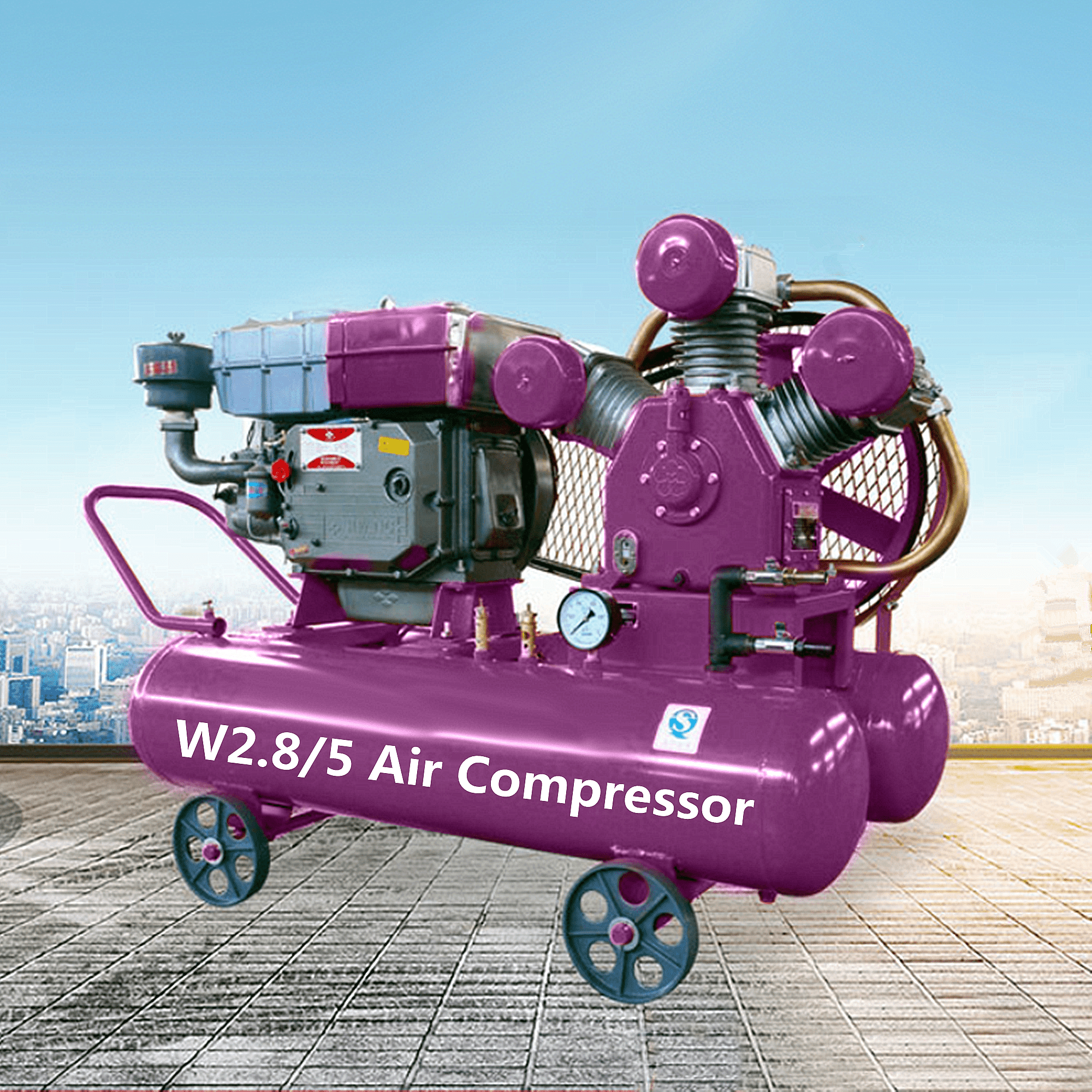

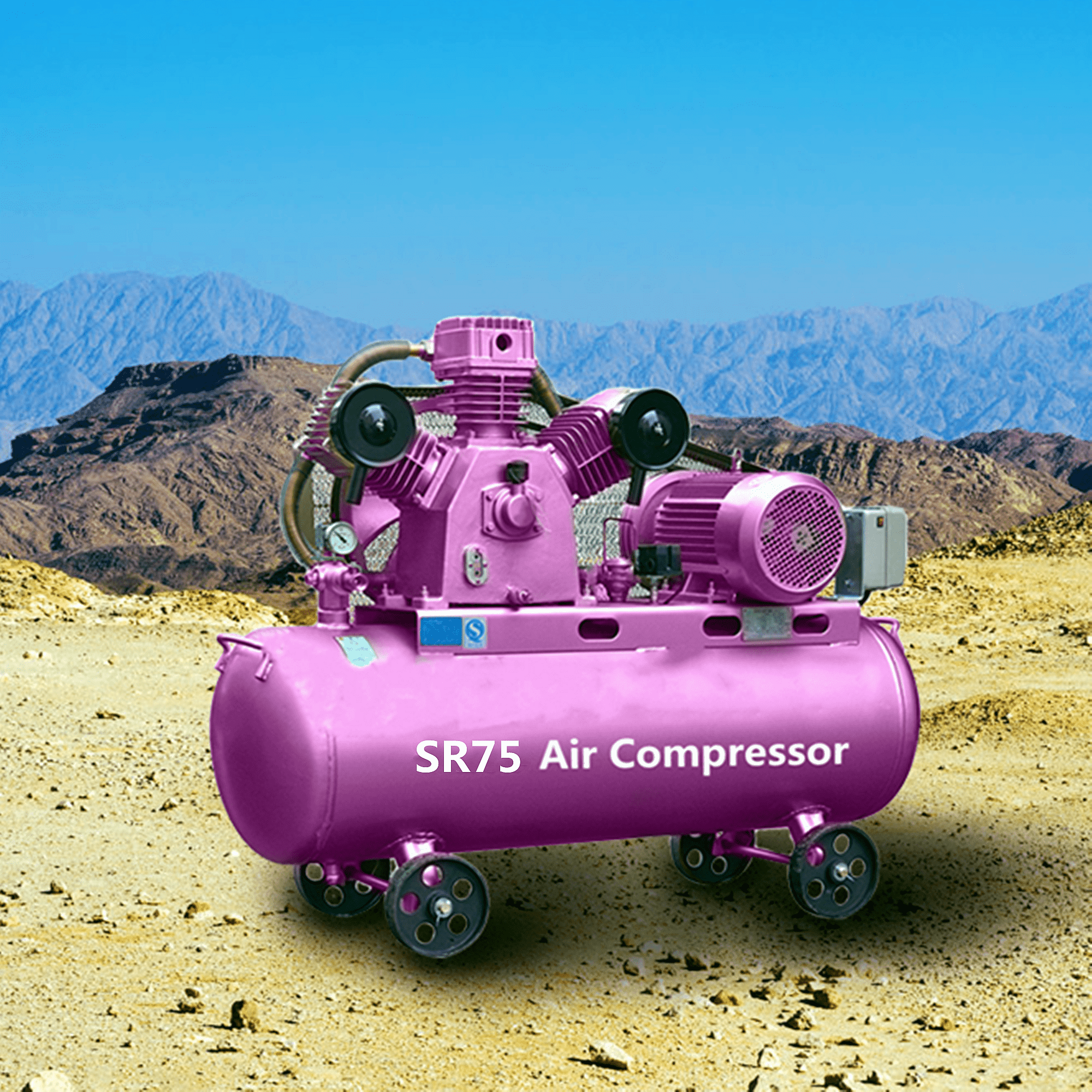

Workshop of Air compressor

Workshop of Automatic Integrated DTH drilling rig

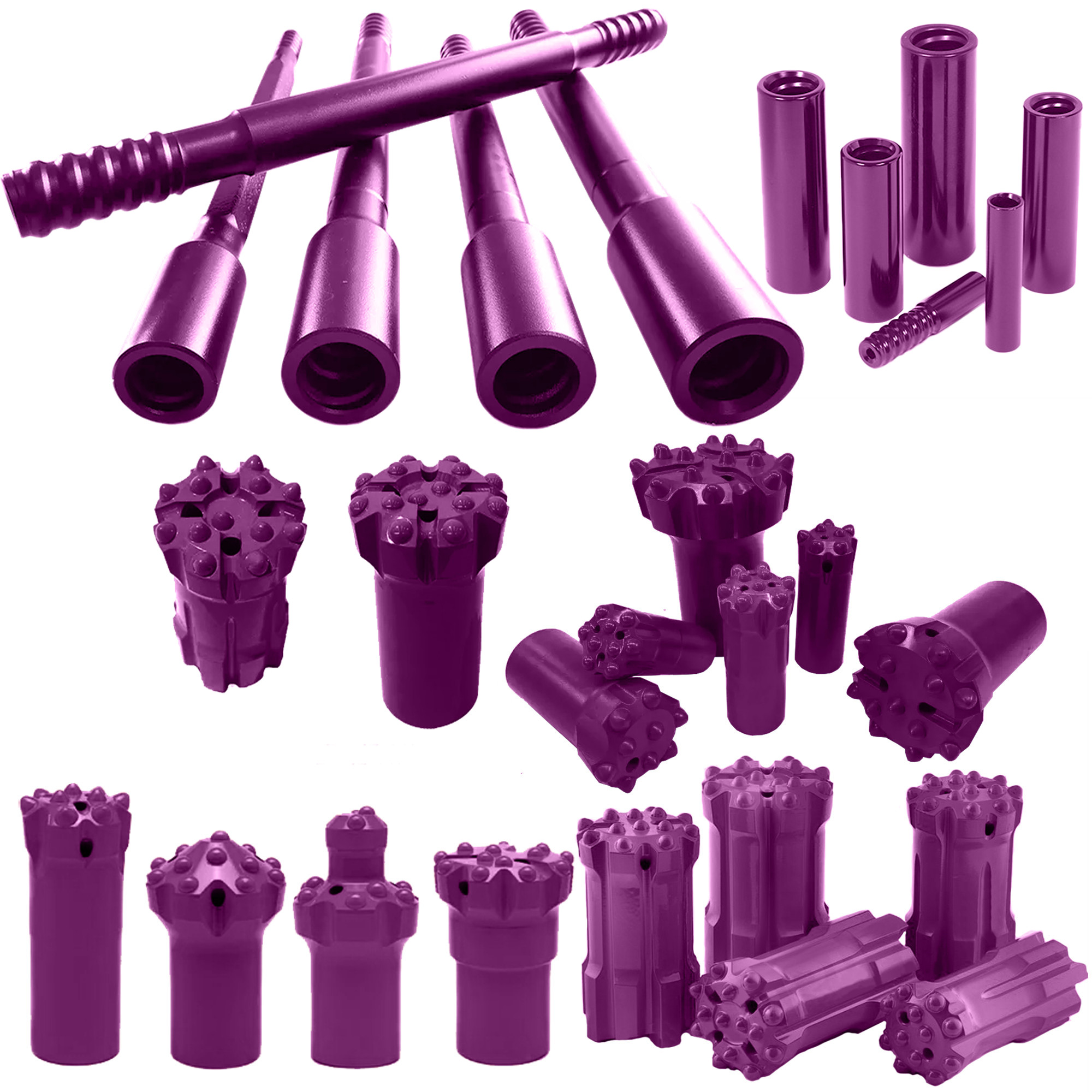

DTH hammer

Workshop of split drilling rig

Load Plate

Vertical View

Phone : +86-5707779993

Tel : +86-15257031180

Email : info@sanrock.com.cn

Whatsapp : 86-15257031180

Copyright 2021 Sanrock Inc. All rights reserved. 浙ICP备2022010184号-1